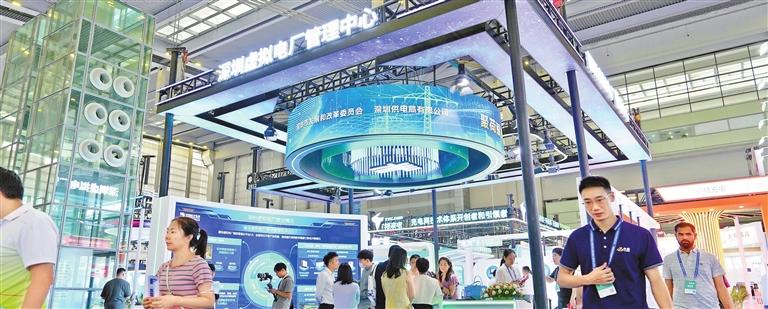

Yang Jingjing, Shu Yucheng, & Ye Zhaokang COMBINING carbon emissions tracking, power dispatching, and intelligent air conditioning load regulation, Shenzhen’s signature energy initiative — the virtual power plant — has received an upgrade again. On Sept. 8, during the 2024 International Digital Energy Exhibition, the Shenzhen Municipal Development and Reform Commission and the Shenzhen Power Supply Bureau of China Southern Power Grid Co. unveiled the virtual power plant regulation and management cloud platform 3.0 (hereinafter referred to as the “3.0 platform”). This initiative aims to promote the development of the virtual power plant industry in a greener, more efficient, and more digital manner. Tracking the ‘carbon footprint’ for a greener electricity supply “The Shenzhen virtual power plant regulation and management cloud platform was launched at the end of 2021 and serves as the ‘commander-in-chief’ of the city’s virtual power plants. Building on the version 2.0 released last year, we have made iterative improvements, particularly in the ‘low-carbon dispatch’ mechanism, which is a significant area of research in the industry,” said Cheng Renli, general manager of the Shenzhen Virtual Power Plant Management Center. By utilizing a combination of “power + computing power” technologies such as green power tracking and remote signaling, the 3.0 platform can initiate processes at local power generation sources, calculating and monitoring the “carbon footprint” throughout the power transmission lifecycle. It integrates carbon emissions data from the power system with current supply and demand conditions, enabling scientifically informed peak load shifting designed to minimize carbon emissions. “Electricity generated from a thermal power plant in western Shenzhen is transmitted to the grid via a substation, with low-carbon dispatch of surrounding load resources being a priority,” said Huang Guanglei, a staff member at the Shenzhen Virtual Power Plant Management Center. Upon addressing an overload situation locally, Huang discovered that the carbon emissions factor of a nearby charging station was high. Utilizing the 3.0 platform to prioritize load reduction, he achieved a reduction of 23 kWh, leading to a decrease of 9,300 grams of carbon emissions, equivalent to the annual carbon sequestration of one tree. As of August this year, Shenzhen’s virtual power plant regulation and management cloud platform has completed 71 load adjustments, resulting in a carbon dioxide emissions reduction of 2,273 tons. The implementation of the low-carbon dispatch function is expected to promote further energy conservation and emissions reductions, with a goal of cutting carbon dioxide emissions by an additional 3,000 tons this year. Enhancing efficiency through extensive digitalization Currently, the 3.0 platform has connected to 55,000 adjustable load resources across nine categories, including charging stations, air conditioners, and photovoltaics. This network boasts a total capacity exceeding 3.1 million kilowatts — 60 times greater than when the platform first launched in 2021 — necessitating enhanced data processing capabilities. According to Li Jiangnan, manager of the Shenzhen Virtual Power Plant Management Center, the platform’s data processing capacity has drastically increased from 100,000 at launch to millions, significantly improving overall response times to the millisecond level. Air-conditioning loads comprise 4% of all adjustable load resources, representing a substantial presence with significant adjustable potential. Shenzhen aims to achieve a regulation capacity of over 200,000 kilowatts from air-conditioning resources connected to the platform by the end of this year, which would meet the electricity demands of more than 40,000 residents. Accordingly, the Shenzhen virtual power plant regulation and management cloud platform has been further optimized to manage air-conditioning loads effectively. Activating the 3.0 platform reveals a detailed map of Shenzhen, showcasing the locations of buildings integrated with air-conditioning resources connected to the virtual power plant. By clicking further, users can instantly access clear data on the energy consumption and operating load of each building. “All of this is made possible by the solid foundation of the digital grid,” said Li Jiangnan. This functionality allows for remote and precise adjustments to the air-conditioning load of specific buildings during power grid emergencies, enabling emergency peak shaving while maintaining comfort levels and increasing economic benefits for users. Moreover, to enhance reliability in power supply, the Shenzhen Virtual Power Plant Management Center is categorizing the existing 55,000 adjustable load resources into various types. This classification will aid in the creation of virtual peak load units and frequency modulation units, which can swiftly mobilize load resources during emergencies. Currently, the adjustable capacity of the 3.0 platform exceeds 700,000 kilowatts. Looking ahead, the Shenzhen Virtual Power Plant Management Center plans to activate the adjustable capacity of charging and swapping equipment, establishing a two-way interactive system for information and energy flow between new energy vehicles and the power grid. It is anticipated that by the end of this year, the Shenzhen virtual power plant regulation and management cloud platform will reach its target of 1 million kilowatts of adjustable capacity, one year ahead of schedule. This will better support Shenzhen in its ambition to become a global digital energy pioneer city. What is a virtual power plant? A virtual power plant is a digital energy management system that integrates “internet + source-grid-load-storage.” It aggregates and optimizes idle power load resources at the user -end level, such as charging stations, air conditioners, and distributed photovoltaics, functioning similarly to a “cloud power plant.” By directly managing these extensive and dispersed power load resources, load regulation can be achieved within a specific timeframe, thereby ensuring the safe and stable operation of the power grid. In August 2022, China’s first virtual power plant management center was established in Shenzhen, within the Shenzhen Power Supply Bureau of China Southern Power Grid Co. It is managed by the Shenzhen Municipal Development and Reform Commission, marking a new phase of rapid development for Shenzhen’s virtual power plant. 3.0 platform in digits 55,000 adjustable load resources Currently, the 3.0 platform is connected to 55,000 adjustable load resources across nine categories, including charging stations, air conditioners, and photovoltaics. 3.1 million kilowatts This network boasts a total capacity exceeding 3.1 million kilowatts — 60 times greater than when the platform first launched in 2021 — necessitating enhanced data processing capabilities. 2,273 tons of CO₂ As of August this year, Shenzhen’s virtual power plant regulation and management cloud platform has reduced carbon dioxide emissions by 2,273 tons. 71 load adjustments As of August this year, Shenzhen’s virtual power plant regulation and management cloud platform has carried out 71 load adjustments. 700,000 kilowatts Currently, the adjustable capacity of the 3.0 platform exceeds 700,000 kilowatts. 3,000 tons of CO₂ Launching the low-carbon dispatching function will achieve greater energy conservation and emission reductions and is expected to reduce carbon dioxide emissions by 3,000 tons this year. |